Blend Chain is used extensively within the cement, paper and pulp, quarrying, and mining industries for elevating and conveying a broad wide range of abrasive and non-abrasive elements. It’s also ?nding lots of utilizes on the whole in-dustrial assembly conveyors. It is actually not advisable for drive chain.

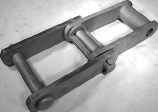

The development of Mixture Chain is often either cottered or riveted. Cottered is ordinarily consid-ered conventional. Pins have ?at regions at their ends, which lock into the appropriately punched sidebars, preventing pin ro-tation for the duration of chain operation. All pin holes are clean-cored for smooth bearing surfaces and therefore are dimensioned for appropriate pin clearance. Sector dimensional requirements are rigidly maintained and this chain could possibly be interchanged with backlinks of other manufacturers.

Pitch sizes range from 1.631 to six.050 inches; tensile power selection extends from 12,150 to 67,500 lbs. All Blend block hyperlinks except C55 and C55L have elliptical barrels. This adds further metal in which the sprocket to chain get in touch with brings about most chain wear.

MBP 132C has chambered barrels containing grease which lubricates pins, helps to avoid joint freezing, and pro-hibits entry of corrosive and abrasive material to the bar-rel core.

Attachments can be found in lots of on the pitch sizes for any broad range of applications.

Combination links are symmetrical and may for that reason be operated in both route of travel.

Brutaloy and cast steel sprockets are available for each pitch size.

Coupler links are necessary for joining chain in which no take-up is obtainable. Every chain pitch dimension includes a Promal cast off-set sidebar coupler link readily available for this goal.