Description

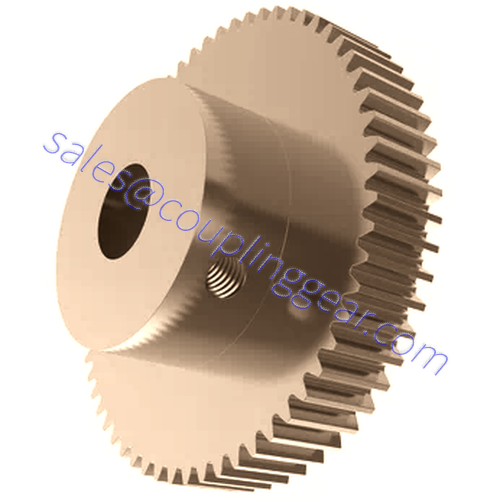

0.8 MOD – 30 Teeth – 7mm Face Width, B1-Type Precision Spur Gears – Brass Technical Specification

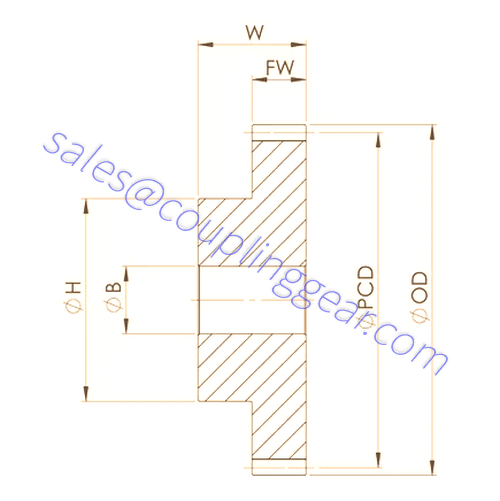

| Bore Diameter (B) | 5mm |

| Face Width (FW) | 7mm |

| Fastening Type | Round Bore, M3 (Set Screw Sold Separately) |

| Finish | Natural |

| Grade | 9/10 |

| Hub Diameter (H) | 12.5mm |

| Hub Type | Solid |

| Material | Brass |

| Material Specification | Brass, CuZn38Pb2/CuZn39Pb3 |

| Number of teeth | 30 |

| Outside Diameter (OD) | 25.6mm |

| Pitch | 0.8 MOD |

| Pitch Circle Dia. (PCD) | 24mm |

| Pressure Angle | 20 degrees |

| Sold As | Individual |

| Width (W) | 14mm |

0.8 MOD – 30 Teeth – 7mm Face Width, B1-Type Precision Spur Gears – Brass Description

The 0.8 MOD – 30 Teeth – 7mm Face Width, B1-Type Precision Spur Gears – Brass has the following features:

- 25.6mm Outside Diameter (OD)

- Brass Material

- Brass, CuZn38Pb2/CuZn39Pb3 Material Specification

- 0.8 MOD Pitch

- 14mm Width (W)

- 30 Number of teeth

- 5mm Bore Diameter (B)

- 7mm Face Width (FW)

- 20 degrees Pressure Angle

- 24mm Pitch Circle Dia. (PCD)

- 12.5mm Hub Diameter (H)

- Natural Finish

- 9/10 Grade

- Individual Sold As

- Round Bore, M3 (Set Screw Sold Separately) Fastening Type

- Solid Hub Type

Discover More About The Spur Gears Range.

Spur Gears are sold in individual pieces and are one of the most fundamental components in any parallel drivetrain. This range includes simple round Gears, which are highly versatile, and frequent use in many power transmission mechanisms. Spur Gears can be used in a gear train to transmit rotary motion or a Precision Rack to convert rotary motion into linear motion. Spur Gears can be accurately spaced using supporting components such as Spacers or Shim Washers.

Spur Gear Materials

Spur Gears can be manufactured from a wide range of materials, including Mild and Stainless Steel, Brass, and engineering plastics, such as Delrin 500, Nylon 6, and Hostaform C.

Spur Gear Sizing

This range of Gears is available in pitches ranging from 0.5 MOD up to 8 MOD and teeth numbers of between 12 and 150. These components are manufactured to a grade 9 AGMA standard, with non-standard sizes and modifications available on request.