Description

We manufacture various chain sprockets and have a strong processing capacity to ensure good quality and competitive prices.

1. American Standard, European Standards, Japanese Standards

2. Pilot bore, finished bore, taper bore, and special bore available

3. Bright surface and high precision

4. Advanced heat treatment and surface treatment crafts

5. Better quality and competitive price.

6. Material C45(1045), low carbon steel, 40Cr, 20CrMnTi, stainless steel such as SS316L, SS316, SS304, SS420, copper, etc. available

7. Standard seaworthy package to Europe and American

8. High-speed digital gear hobbing machines to guarantee the teeth quality

9. Corrosion resistance treatment available

10. Control on tolerance and easy to install

11. Good material and good treatment to make sure long life span

12. OEM/ODM welcome

| Product | Steel roller chain sprockets |

| Teeth | 9T- 120T |

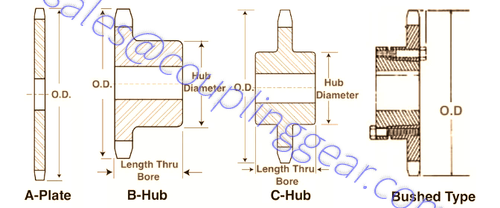

| Sprockets Type

(The pictures areas below) |

Type A sprockets: Plate (without Hub) |

| Type B sprockets: One side with Hub | |

| Type C sprockets: Double side with Hub | |

| Finished bore sprockets: With the inner hole, keyway, and screw | |

| Sprockets Size | ANSI: 25/35/41/40/50/60/80/100/120/140/160/180/200/240 |

| DIN/ISO:04C/06C/085/08A/10A/12A/16A/20A/24A/28A/32A/36A/40A/48A | |

| DIN/ISO:04B/05B/06B/08B/10B/12B/16B/20B/24B/28B/32B/36B/40B/48B/56B, | |

| Material: | Alloy Steel, Carbon Steel, Stainless Steel, Aluminum, Copper, Brass |

| Heat Treatment | Hardening and Tempering, High-Frequency Quenching, Carburizing Quenching |

| Surface Treatment | Galvanizing/Zinc Plating, chrome-plated, Black oxide Treatment |

| Process | Forging, Hobbing, Precision machining, |

| OEM | Supported |

| MOQ | One piece |

Sprockets are used in bicycles, motorcycles, cars, tracked vehicles, and other machinery to transmit rotary motion between two shafts where gears are unsuitable or impart linear motion to a track, tape, etc. Perhaps the most common form of sprocket may be found in the bicycle, in which the pedal shaft carries a large sprocket wheel, which drives a chain, which, in turn, causes a small sprocket on the axle of the rear wheel. Early automobiles were also primarily driven by sprocket and chain mechanisms; a practice essentially copied from bicycles.