Description

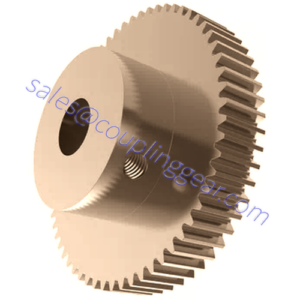

With helical gearing, the teeth mesh gradually and at no period is the entire width of any one tooth wholly engaged. This gradual engagement and release of the teeth eliminate much of the shock and jar associated with straight spur gear teeth when operating under heavy loads. The shaft support bearing design has to be more substantial than a spur gear drive because of the end load produced when in operation. The bag is in opposite directions from one shaft to the next in a helical gear combination or train of gears. Single helical gears are mainly mounted on parallel shafts but can be mounted on poles at 90 degrees (as you would find in a worm and wheel shaft arrangement) or at any angle between 0 and 90 degrees. These gears are sometimes known as spiral or skew helical gears.

Product detail:

|

Product name

|

Helical Gear

|

|

Type

|

spur/helical/bevel/worm gear

|

|

Model

|

M0.5-M8

|

|

Pressure angle

|

20 degree

|

|

Precision grade

|

DIN7 DIN6

|

|

Materials Available

|

Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy,Copper,Plastic,Nylon,PA66,MC,PEER,MSM,POM,Derlin etc

|

|

Heat Treatment

|

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding……

|

|

Surface Treatment

|

Carburizing and Quenching, Tempering, Tooth surface high quenching Hardening, Tempering

|

|

Bore

|

Finished bore, Pilot Bore, Special request

|

|

Applications

|

Electric machinery, metallurgical machinery, environmental protection machinery, electronic and electrical appliances, road

construction machinery, chemical machinery, food machinery, light industrial machinery, mining machinery, transportation machinery, construction machinery, building materials machinery, cement machinery, rubber machinery, water conservancy machinery and petroleum machinery |

Features:

- The teeth of the helical gear are longer and more robust than the other, which makes it more efficient.

- They are preferred for high-speed applications.

- A comprehensive contact line enables the helical gears for carrying the high load.

- These gears do not need LSD oil rather than ordinary oil

- Such bags can exceed the speed of 50ms when they are correctly machined and balanced.

- The longer the angle, the smoother the operation, and the higher speed is possible; however, the thrust loadings on the supporting bearings also go up.

- Helical is the crucial component to obtobtainingcompact, lightweight, simple configuration of the machines.

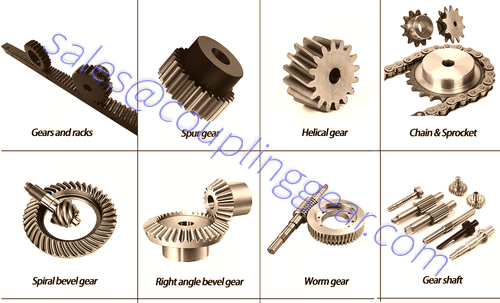

Related products

Production workshop

Q: Are you a trading company or a manufacturer?

A: Our group consists of 3 factories and two abroad sales corporations.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free but do not pay the freight cost.

Q: How long is your delivery time? What are your terms of payment?

A: Generally, it is 40-45 days. The time may vary depending on the product and the level of customization. The payment is 30% T/T in advance for standard products and the balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs. Thus, MOQ and price may greatly vary with size, material, and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please get in touch with us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.