Description

|

Specification

|

|

|

Precision grade

|

ISO grade 5, AGMA grade 13

|

|

The reference section of the gear

|

Normal plane

|

|

Gear Teeth

|

Standard full depth

|

|

Pressure angle

|

20°

|

|

Helix angle

|

—-

|

|

Material

|

SCM415, 15CrMo, 9310,8620

|

|

Surface treatment

|

Black oxide coating

|

Products Description

|

Gear Ratio

|

Module (M)

|

No. of teeth

|

AH7

|

Hub (B)

|

Pitch dia. (C)

|

Outside dia. (D)

|

Mounting distance (E)

|

Total Length (F)

|

|

1

|

1

|

20

|

8

|

17

|

20

|

21.29

|

20

|

13.53

|

|

1

|

1.5

|

20

|

10

|

25

|

30

|

31.9

|

28

|

18.48

|

|

1

|

2

|

20

|

14

|

35

|

40

|

42.52

|

35

|

22.09

|

|

1

|

2.5

|

20

|

18

|

42

|

50

|

53.2

|

45

|

28.63

|

|

1

|

3

|

20

|

20

|

52

|

60

|

63.99

|

50

|

30.78

|

|

1

|

4

|

20

|

28

|

55

|

80

|

84.99

|

65

|

39.13

|

|

1

|

6

|

20

|

40

|

80

|

120

|

127.59

|

90

|

51.13

|

|

Process

|

CNC machining, CNC milling, CNC lathe machining

|

|

Available Material

|

1.Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420,etc.

|

|

2.Steel: C45, 40Cr, 42CrMo, 20CrNiMo, 20CrMnTi, etc. (AISI 1045, 5140, 4140/4142, 8620 etc.)

|

|

|

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200CuZn37), C28000(CuZn40),etc.

|

|

|

4.Bronze: C51000, C52100, C54400, etc.

|

|

|

5. Iron: 1213, 12L14,1215,etc.

|

|

|

6. Aluminum: Al6061, Al6063,Al2025,Al7075 etc

|

|

|

7. Carbon steel:AISI1006,AISI1010,AISI1022,etc.

|

|

|

8.Nylon PA66,MC901,POM plastic acts

|

|

|

Hardness

|

HRC50~55

|

|

Quality Control

|

ISO9001 and ISO14001

|

|

Dimension bore tolerances

|

-/+0.01mm

|

|

Quality standard

|

AGMA, JIS, DIN

|

|

Size/Color

|

Gears and parts dimensions are according to drawings from the customer, and colors are customized

|

|

Surface treatment

|

black oxide,Zn-plated,ni-plated,tin-plated,chrome-plated,passivated,sandblast and anodize,chromate,polish,electro painting,black

anodize,plain,H.D.G,etc. |

|

Dimensions Tolerance

|

±0.01mm or more precise

|

|

Samples confirmation and approval

|

samples shipped for confirmation and shipping cost paid by customers

|

|

Package

|

Inner clear plastic bag/outside carton/wooden pallets/ or any other special package per customer’s requirements.

|

If you need other customized requirements, please click here to contact us!

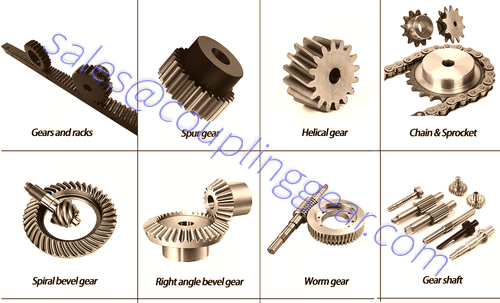

Types of Gears

Customization process

Support Customized Gears from Customers’ drawings and samples and Various non-standard customization

1. Products Discussions

1. Products Discussions

Customers send drawings or samples and quote according to customers’ requirements.

2. Molds designing

Designing 3D drawings and optimizing the products.

3. Drawing confirmation

Sending the mold drawing to the customers and the customer’s signature for confirmation.

4. Molds Construction

Manufacture molds accurately and accurately according to the drawings.

5. Moulds Inspection and Moulds Test

Detect various indicators of molds and optimization of inner cavities.

6. Sample Approval from Customer

Customers approve the samples and confirm them for bulk production.

7. Mass Production

Bulk production according to customers’ PO

8. PO Finished

Shipping to the customer and the customers receive the gears.

2. Molds designing

Designing 3D drawings and optimizing the products.

3. Drawing confirmation

Sending the mold drawing to the customers and the customer’s signature for confirmation.

4. Molds Construction

Manufacture molds accurately and accurately according to the drawings.

5. Moulds Inspection and Moulds Test

Detect various indicators of molds and optimization of inner cavities.

6. Sample Approval from Customer

Customers approve the samples and confirm them for bulk production.

7. Mass Production

Bulk production according to customers’ PO

8. PO Finished

Shipping to the customer and the customers receive the gears.