High energy roller chains with enhanced fatigue strength and impact strength

HI-PWR-S roller

Proposed employs

?Compared to conventional roller chains, HI-PWR-S roller chains are greater in maximum kilowatt rating by about 30 % in a medium to low velocity range. They exhibit superb capability in destinations wherever substantial shock loads are applied, drive units for frequent start/stop, as well as in large velocity applications.

?Civil engineering machines this kind of as skid steer, trenchers, trucks, cranes, agitating trucks, forklifts and drive units for conveyors, elevators, stackers, and so forth.

Collection of chains

On the whole, select your chain with reference to “Designing of Chain Transmission” and also to your tables of “Drive Performance” and “Dimensions” of HI-PWR-S style roller chains.Nevertheless, only for a specific situation of minimal pace and much less shock, “Low-speed selection” is additionally applicable.

Sprockets

HI-PWR-S Roller chains and ANSI typical chains are the identical in standard dimensions. Use ANSI typical sprockets.

Connecting back links and offset back links

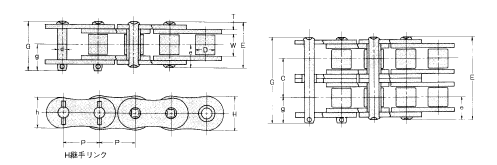

Use H connecting hyperlinks for HI-PWR-S. In an H connecting hyperlink, the pins are lightly interference-fitted with the connecting plate. For your connection involving the connecting plate along with the connecting pins, spring pins are employed instead of cotter pins for a regular roller chain.

The center plates of an H connecting link for multiplex chain has bushings pressed in.

HI-PWR-S roller chains don’t have any offset link. Use an even amount of links.

Never ever make the holes of your connecting plate more substantial and never make the pins thinner to facilitate the function for fitting the pins into the connecting plate, since otherwise the fatigue power are going to be lowered.