Description

Overview of PAD Planetary Gear Reducer

- PAD series features high precision and low backlash

- PAD series adopts integral ball bearings to realize high rigidity and high torque

- Due to the use of tapered needle roller bearing, it achieves a high load capacity.

- The PAD Speed reducer can be matched with any brand of motor.

- Free maintenance and long service life

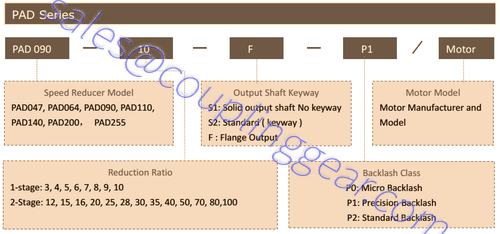

Indication of Model Numbers of PAD Speed Reducers

Description of PAD High Precision Planetary Gearboxes

famed PAD high precision planetary gearbox is a kind of flange output and high precision gearbox, with the features of high rigidity, high torque, high load capacity, and low backlash, which guarantees dynamic performance in the running process and is widely applied in motion control industries.

Due to the features of high precision positioning, the PAD series planetary reducer is particularly suitable for dynamic cyclic operations and compact solutions for motion control, automation, and robotics.

There are many advantages of the PAD high precision planetary gearbox; Highest torsional stiffness, tilting moment, and compactness are the main characteristics of the PAD series. It is a perfect solution for dynamic cycle operation, motion control, automation, and robotics.

- If the motor shaft diameter is different from the input shaft diameter, it can be matched with the shaft sleeve.

- PAD planetary speed reducer can be matched with different servo motors and stepper motors like Panasonic, Mitsubishi, Yaskawa, Taida, Fuji, etc.

Application of PAD High Precision Planetary Reducers:

These PAD planetary reducers have been generally applied in machine tools, industrial robots arm, loader robots, printing machines, medical equipment, measuring equipment, gantry robots, automotive industry, sealing machines, etc.

How to Select the Right Speed Reducer?

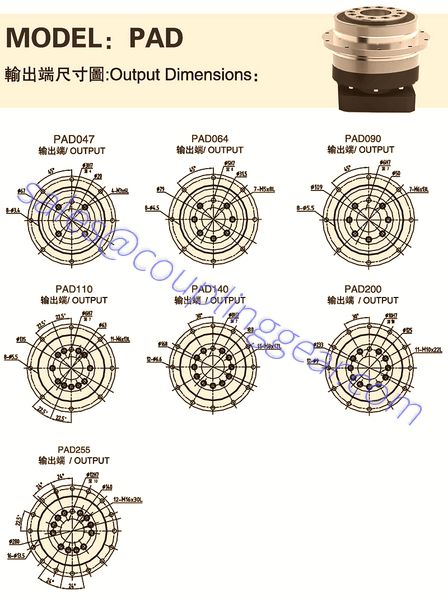

Catalog of PAD Precision Speed Reducer

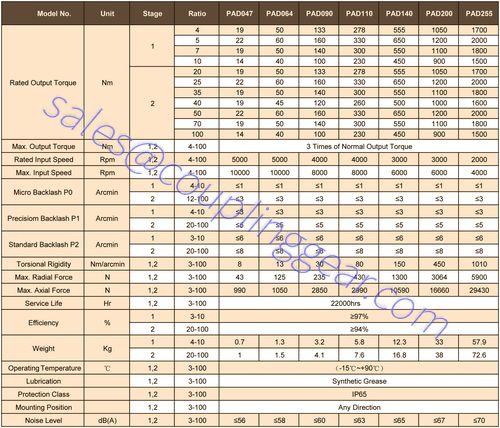

Specification Table of VRB Planetary Gear Reducer