Description

Worm wheels always accompany a worm. A worm and wheel combination is another method of driving two shafts; the axes typically lie at right angles. The usual driving member, the worm, may have either a single or multi-start thread. A worm wheel can be produced by hobbing with a hob designed for a specific worm size, the number of stars, and the hand of the helix. The hob feed can be either plunge (radial), divergent (axial), or both. This production method is quicker than using a fly tool (fly hob), a single-point tool. Suppose the worm wheel is a multi-start and not a hunting tooth (when the result of the number of teeth in the wheel divided by the number of stars in the worm is not an integer number). In that case, when using a fly tool, the worm wheel has to be indexed into the next lead, and it is as if the worm wheel is cut again and repeated until all the tips (starts) are missed. It is cheaper to make a fly tool than a hob but takes longer to cut the worm wheel. Hobs are usually used for large batch sizes when the cost of the hob can be amortized over a more significant number of components.

Worms are like a screw thread and work with worm wheels, or they can be used to gear with a single helical gear. A single helical gear is cheaper to make than a worm wheel, but the resultant drive is not as good, and it will not last as long in service.

|

Product name

|

Factory Custom Precision Worm And Worm Wheel

|

|

Material

|

Custom Metal or Plastic

|

|

Finish

|

Clean or Customized

|

|

Process

|

Machining, Hobbing or Sintered, injection-molded,

|

|

Tolerance

|

±0.1mm

|

|

Certification

|

ISO9001:2008,SGS, ROHS

|

|

Package

|

PP bag, carton, box, or according to customer’s requirements

|

|

Usage

|

Worm and Worm Wheel

|

|

MOQ

|

10 Sets

|

|

Sample

|

Available

|

|

Shipping

|

Shipped conveniently and cost-effectively.

|

|

Custom

|

OEM/ODM available in Shenzhen

|

|

Mainly Line

|

Precision CNC Machining, Precision Stamping Parts, Plastic Injection Molding, Hardware,

|

Feature:

1. The transmission structure of the worm shaft is simple, compact, small volume, and lightweight.

2. The worm is made of metal, and the worm wheel is bronze, which has a long service life.

3. If you need more torsion or slower output speed, you can use it to replace the standard 4: 1 worm gear for the worm gearbox.

4. Similarly, the equipment reduces the chance of reverse drive to almost 0.

5. The worm gear is mounted on a 4.7 mm D-axle diameter. The worm is mounted on a 6mm or 4.7mm D-shaped shaft.

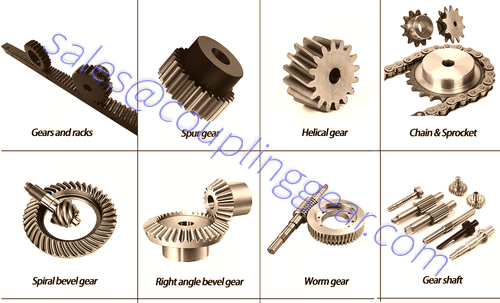

Other related products

Q: Are you a trading company or manufacturer?

A: Our group consists of 3 factories and two abroad sales corporations.

Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free but do not pay the freight cost.

Q: How long is your delivery time? What are your terms of payment?

A: Generally, it is 40-45 days. The time may vary depending on the product and the level of customization. The payment is 30% T/T in advance for standard products, balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs. Thus, MOQ and price may greatly vary with size, material, and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please get in touch with us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.